Complete AC and DC Power Test Infrastructure: Advanced, Regenerative and Fully Integrated

REGATRON has successfully delivered a comprehensive and fully regenerative power testing solution to IEP, Instituto Electrotécnico Português, one of Portugal’s leading certification and research laboratories in the field of electrical and electronic testing.

The installation includes three independent but complementary test systems:

- EMC AC compliance testing

- High-power DC testing for automotive standards

- Electrochemical Impedance Spectroscopy (EIS)

The Components of the System

a) EMC AC Compliance Testing

The AC testing platform at IEP is based on the REGATRON TC.ACS programmable three-phase power supply, combined with the EMC standards test package, the TC.FLK flicker impedance network, and the TC.VSE voltage slope enhancer.

Together, these units form a turnkey EMC compliance system for harmonic current, flicker, and voltage dip and variation testing according to IEC/EN 61000-3 and 61000-4 standards.

The TC.FLK impedance network precisely reproduces the reference and test impedances defined by the standards, while the TC.VSE module enables fast voltage transitions below 5 microseconds and current peaks up to 1000 amperes, as required for full-compliance immunity testing.

Controlled through the ACSControl software suite, the system allows engineers to execute standard test profiles, visualize waveforms in real time, and automatically generate compliance reports. The result is a reliable and efficient EMC testing workflow for certification and product validation.

b) High-Power DC Testing

The DC section is based on the REGATRON G5.UNV series of bidirectional DC power supplies, delivering 400+ kilowatts with full regenerative operation. Thanks to its wide auto-ranging characteristic and bidirectional operation, the system covers a broad range of test scenarios for battery cycling, PV panel and fuel cell emulation, DC grid and converter testing, and up to hardware-in-the-loop environments. The dynamic performance with a switchable output capacitance of the G5 power supplies also allows to be combined with a third-party function generator to perform testing according automotive standards (LV123, VW80300, ISO16750-2, ISO21498-2, etc.). A custom-designed Power Distribution Unit (PDU) enables dynamic allocation of power across multiple test benches.

This allows several experiments to be performed in parallel, providing maximum throughput and laboratory flexibility. Control and automation are implemented through the application software G5.Control and G5.API, ensuring precise synchronization and seamless integration into IEP’s laboratory management system.

Eight REGATRON G5.UNV units provide a total of 400+ kW DC power.

Prefabricated connection panels are shown on the right side of the picture for easier connection of power cables in four different test areas. A DC voltage level indicator and full integration into the emergency stop circuit complete the range of functions offered by the power distribution units.

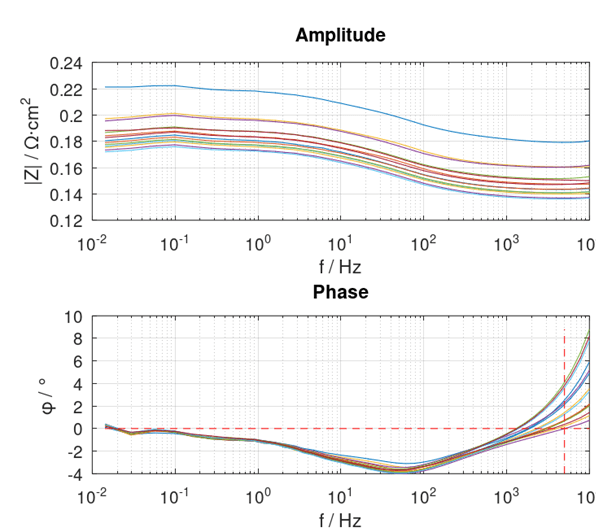

c) EIS Battery Test System

A dedicated setup for electrochemical impedance spectroscopy completes the installation. Based on the REGATRON G5 platform, the system enables superimposed AC modulation up to 10 kHz on a controlled DC operating point without requiring external modulators. Specialized EIS measurement systems and analysis software can also be offered in collaboration with Regatron’s partners.

This functionality allows detailed analysis of internal resistance and impedance of battery cells, frequency-dependent behavior of electrochemical components, and stack uniformity and degradation mechanisms. Such capability, previously demonstrated by HyCentA Research in Austria, provides research-grade measurement accuracy within a single programmable power platform.

From Concept to Commissioning

Beyond the hardware, this project illustrates REGATRON’s comprehensive engineering and customer support process, which accompanies the customer from the initial concept to full operation. The complete solution was defined and configured according to IEP’s specific testing and certification requirements by Regatron’s engineering team and its application-specific collaboration partners in the field of automotive standards, EIS, and EMC testing.

A factory acceptance test was carried out at REGATRON’s headquarters in Rorschach, Switzerland, validating performance and functionality in cooperation with IEP’s engineers. Following delivery, REGATRON’s technical team completed the on-site commissioning and operator training at IEP’s facility in Portugal, ensuring full system integration and readiness for daily operation.

This approach reflects REGATRON’s commitment to providing reliable, long-term solutions through close technical collaboration at every stage of the project.

A Reference for Advanced Certification in Portugal

The decision by IEP to equip its laboratory with REGATRON systems underscores the institute’s confidence in the quality, performance, and long-term reliability of the well-known REGARON technology. This project sets a new benchmark in Portugal for comprehensive, regenerative, and modular test environments, combining AC and DC power testing, EMC compliance, and electrochemical analysis in a single integrated platform.

REGATRON – Swiss Precision for Future Energy Testing

With its modular architecture, high efficiency, and engineering excellence, RREGATRON continues to empower laboratories and research centers worldwide to advance in power electronics, renewable energy, and e-mobility testing. The successful realization of the IEP project exemplifies REGATRON’s ability to deliver high-performance turnkey test systems tailored to the complex demands of modern certification and research environments.

Have Questions or Looking to Tackle a Similar Challenge?

Reach out to our team — we’re happy to support you with technical expertise, detailed guidance, and solution-oriented consultation.

REGATRON Performance. Precision. Quality.