Safety Discharge for Battery Recycling

From full charge to zero volts – REGATRON’s custom solution for battery end-of-life and recycling applications! Discover more about safe solutions for the disposal and recycling of used high-voltage batteries and storage systems!

Managing high-voltage batteries at end-of-life state presents both significant technical and environmental hurdles. REGATRON, a top manufacturer of programmable bidirectional power supplies, has recently introduced an innovative, custom solution that allows for the safe, fully automated deep discharge of batteries down to zero volts, enabling their neutralization before recycling. This application was successfully demonstrated in the presence of the end user and its technical partners.

The actual main challenge: Electric vehicle batteries retain a significant amount of residual energy, even when designated as ‘discharged.’ In order to safely process these batteries for recycling, particularly under rigorous safety protocols, it is essential to entirely eliminate any remaining charge. The objective was to create a system adept at fully discharging high-voltage batteries in a controlled, automated, and safe manner; culminating in a dependable short-circuit at 0 V.

REGATRON’s Tailored Solution

Leveraging the advanced G5 series technology, REGATRON developed a fully customized battery discharge system combining the bidirectional DC power supply with a newly developed module: the EDU (energy discharge unit). This system performs a complete and programmable discharge cycle, feeding on the one hand the residual charge almost completely back to the grid and, on the other hand, ensuring a full energy neutralization.

Key System Components

- G5.BT.18.1000.54: Programmable bidirectional DC power supply, capable of precisely regulating voltage and current during the regenerative discharge phase.

- Energy storage systems discharge unit (EDU): A custom add-on module developed also by REGATRON, that integrates high-power resistive discharge and final short-circuit functions.

Application and Testing Setup

The demonstration was conducted using EV batteries from a Mitsubishi Outlander, with a nominal voltage of approximately 320 volts. The test setup was installed at a specialized fire safety and emergency training center, ensuring maximum safety during operations.

Application and Testing Setup

- Phase 1: Regenerative Discharge: The battery is discharged at a constant current of 25 A (adjustable), and energy is recovered to the grid using the G5 power supply. This phase continues until the battery voltage drops to 20 V.

- Phase 2: Low-Voltage Discharge: The current is reduced to 15 A ensuring a controlled end of the regenerative process until approaching 4 V.

- Phase 3: Resistive Discharge (EDU): Below 4 V, the EDU activates, engaging precision-calibrated resistors to further lower the battery voltage to 1 V.

- Phase 4: Final Short Circuit at 1 V, the EDU applies a permanent short circuit, ensuring the battery remains fully neutralized at 0 V.

The complete discharge cycle was completed in less than two hours. Users can fully configure all voltage and current parameters, optimizing the process for various battery chemistries, capacity and applicable safety protocols. The automated control and high precision of the G5 + EDU solution guarantee repeatability and adherence to stringent safety standards.

This recent advancement showcases REGATRON’s ability to provide tailored, high-performance solutions rooted in its fundamental power supply technologies. With this all-in-one battery discharge system, REGATRON offers a valuable resource for R&D centers, battery recyclers, and safety testing facilities aiming to manage EV batteries at the end of their life cycle.

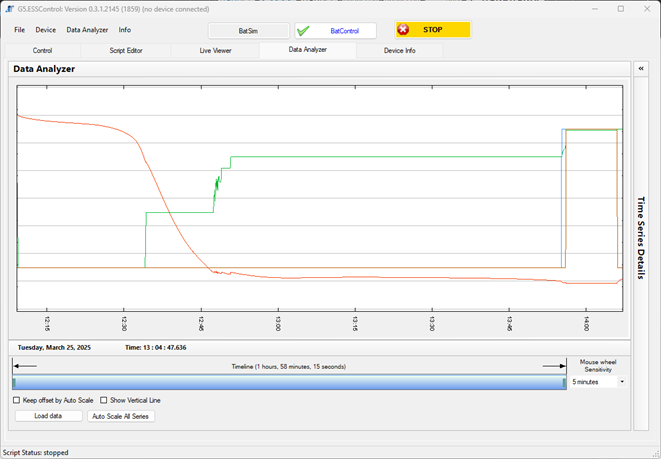

Customization with G5.BatControl Software

For this particular application, the engineers created a customized script within the G5.BatControl software. This script gives users complete control over both the regenerative discharge phase (using the G5 power supply) and the resistive discharge phase (managed by the EDU). By adjusting various discharge parameters, the script allows users to achieve flexibility and precision that’s tailored to different battery chemistries and testing protocols.

The G5.ESSControl software suite features battery testing (G5.BatControl) and simulation (G5.BatSim) functions, highlighting the versatility and adaptability of Regatron’s solutions. This flexibility, combined with our talented engineering team, promotes continuous innovation and the development of advanced solutions for battery recycling and other specialized applications.

Have Questions or Looking to Tackle a Similar Challenge?

Reach out to our team — we’re happy to support you with technical expertise, detailed guidance, and solution-oriented consultation.

REGATRON Performance. Precision. Quality.